WHAT WE DO at MEIFUS INDUSTRIAL

Our business model is based on adapting to our clients in both small and larger projects with the same ease and competence.

In engineering we have successfully realised more than 500 prototypes, more than 20 specific machines and hundreds of engineering hours for products, processes and/or services.

In addition, we have developed several patents for different products, we have been awarded innovation prizes and we are recognised as a partner who provides solutions with a with a good and highly adapted service.

We strive to have the best means and if we don’t have them we look for them. As we have several plants, we are very versatile in order to be able to undertake practically any industrial product or service.

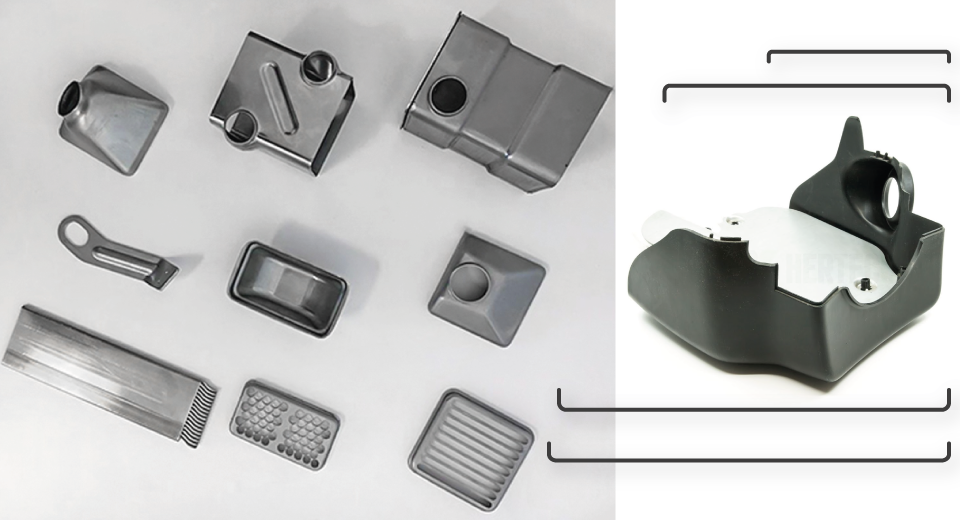

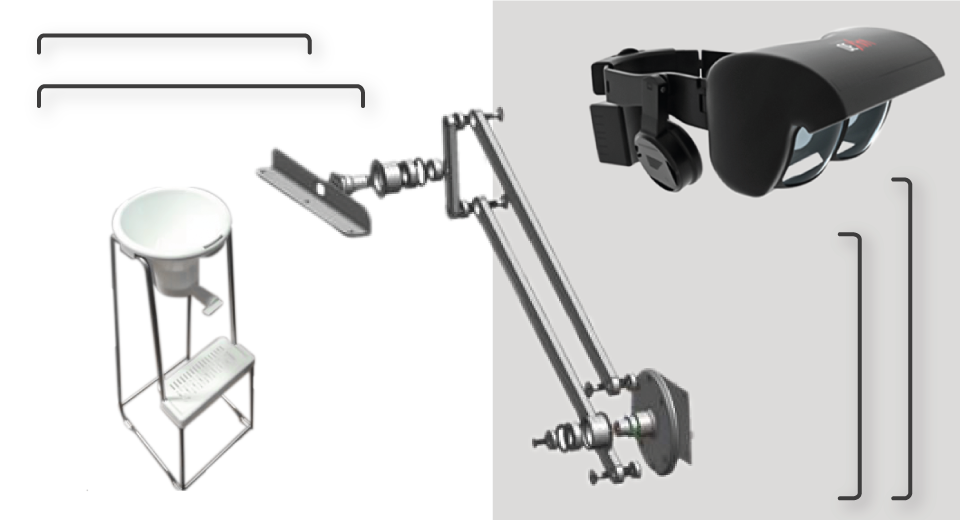

Industrialisation and Prototyping

Production of prototype and series parts in metal (machining, stamping, welding…), plastic (injection, assemblies…), foam (gluing, cutting, thermoforming…) with the possible combination of several technologies and with competitiveness in each one individually.

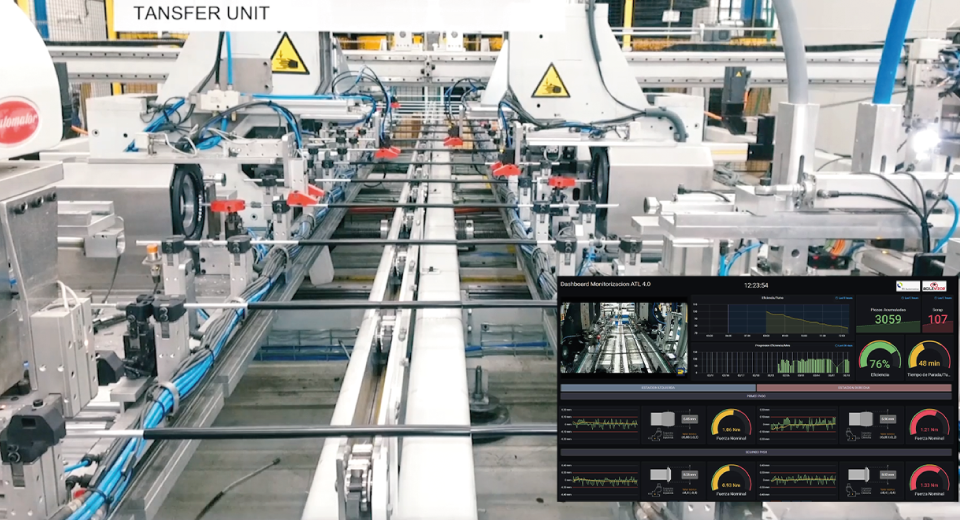

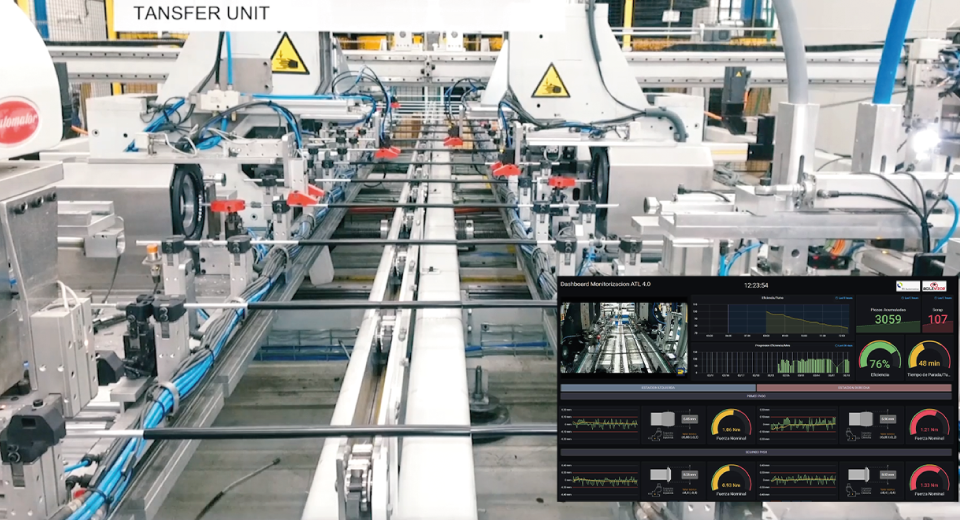

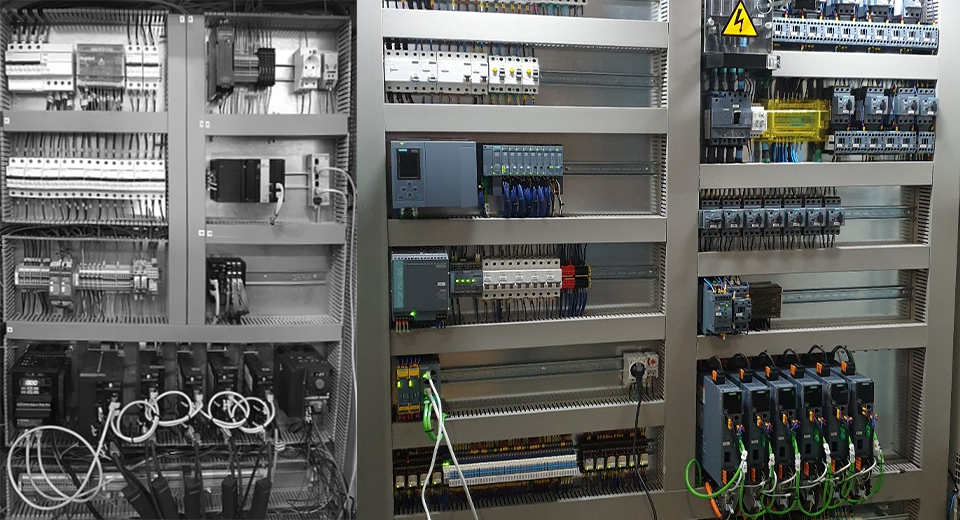

Automation, Sensorization, Virtualization and

Monitoring

Industries are immersed in a process of Industrial Digitalisation.

The information produced by machines is very valuable. We provide you with everything you need to use different techniques (big data, machine learning, predictive analytics, etc.) to store information, analyse data intelligently, increase productivity and efficiency, prevent machine failures and optimise processes.

Automation, Sensorization, Virtualization and

Monitoring

Industries are immersed in a process of Industrial Digitalisation.

The information produced by machines is very valuable. We provide you with everything you need to use different techniques (big data, machine learning, predictive analytics, etc.) to store information, analyse data intelligently, increase productivity and efficiency, prevent machine failures and optimise processes.

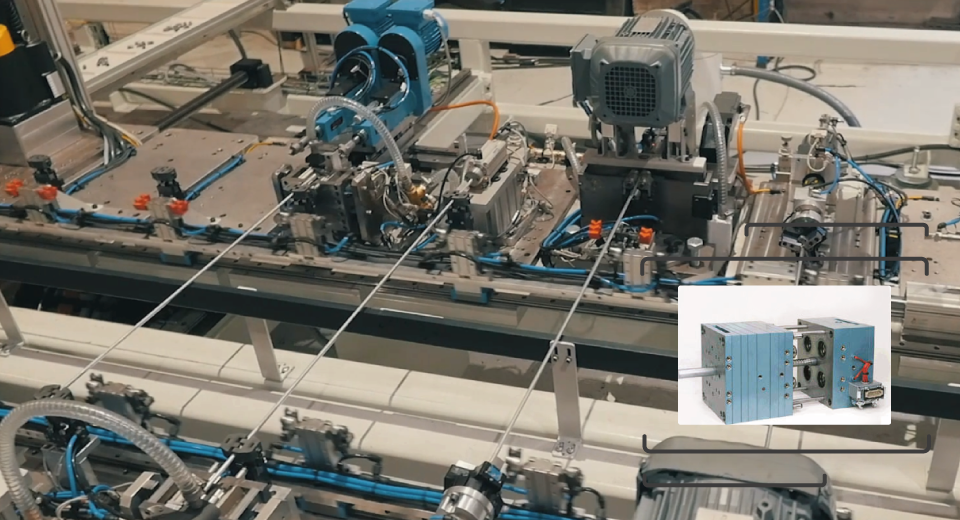

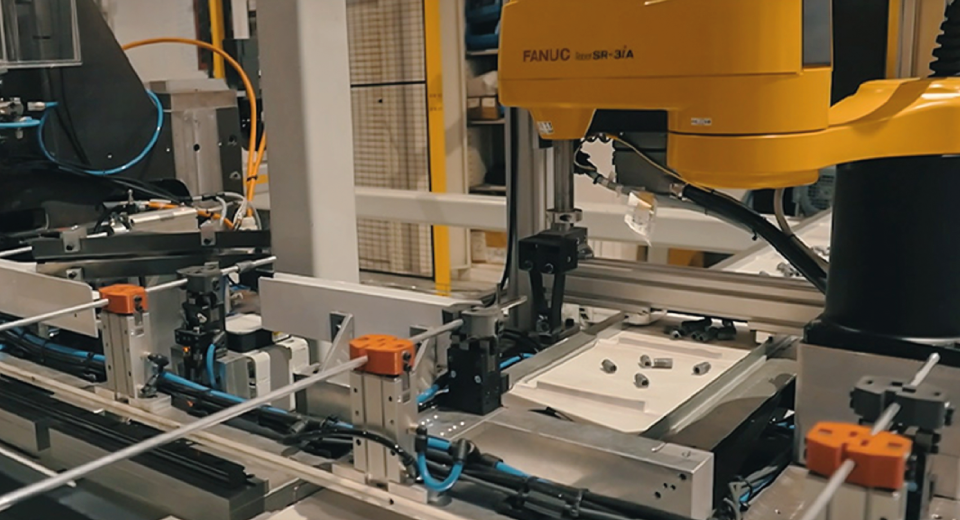

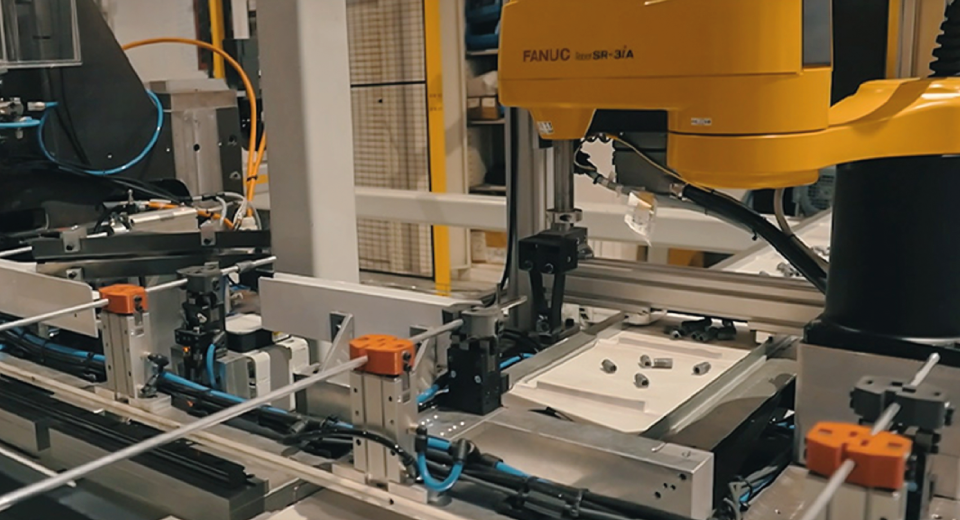

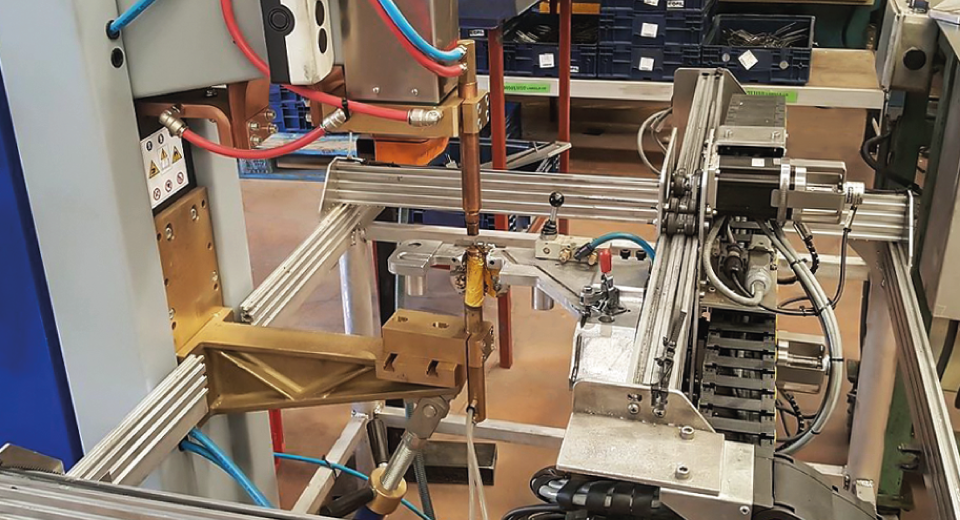

Manufacture of Machines, Tools, Structures and Industrial Equipment

We manufacture any type of specific machine or tooling, complete 4.0 machines as well as equipment and structures required for any type of industry.

Solutions from our engineering with our own workshops for metal fabrication (boilermaking, stamping, welding…), machining (milling machines and CNC machining centres, lathe, grinding…) as well as assembly workshop, electrical and automation workshop.

We master a wide range of technologies and certify all our products.

Engineering I+D+I

We are experts in engineering. Committed to your success, we work hand-in-hand with your teams to analyse your technical requirements throughout each stage of the project lifecycle from start to finish and develop a customised solution for you.

The engineering team provides comprehensive advice and support in choosing the optimum solution to suit your individual needs and requirements. This includes compliance, design and development, renderings, prototypes, testing, performance studies and more.

Engineering I+D+I

We are experts in engineering. Committed to your success, we work hand-in-hand with your teams to analyse your technical requirements throughout each stage of the project lifecycle from start to finish and develop a customised solution for you.

The engineering team provides comprehensive advice and support in choosing the optimum solution to suit your individual needs and requirements. This includes compliance, design and development, renderings, prototypes, testing, performance studies and more.

Serial Industrial Processes

Mass production of goods in large quantities requires the standardisation ofprocesses and procedures on a large scale. A serial process business model makes it possible to produce high quality products quickly and in large quantities, but the infrastructure and other assets needed to support serial production are extremely costly and difficult to manage efficiently. In the Meifus Group we can make almost any type of serial production at a very tight cost and with excellent engineering to adapt the product/process to the real needs of the customer.

Supplies of Materials and Industrial Processes

We have been adapting to our customers and are able to offer any size and quantity of the 16 families we have. We are competitive in all our families and are able to be competitive in any quantity demanded.

We aim to be a very dynamic warehouse with a clear idea of service to help our customers to be more productive.

We have a strong warehouse vocation and we aim to be our customers’ warehouse. To this end, we are at your complete disposal to always and at all times have the products you require at the best price, with full traceability and immediate delivery.

We can guarantee the existence and availability in our warehouse of all products that have been previously requested by our customers and thus we can ensure a permanent stock of them without any obligation to purchase.

This makes us a great partner with a great service.

We are a partner for our customers.

We are: MUCH MORE THAN A WAREHOUSE.

Supplies of Materials and Industrial Processes

We have been adapting to our customers and are able to offer any size and quantity of the 16 families we have. We are competitive in all our families and are able to be competitive in any quantity demanded.

We aim to be a very dynamic warehouse with a clear idea of service to help our customers to be more productive.

We have a strong warehouse vocation and we aim to be our customers’ warehouse. To this end, we are at your complete disposal to always and at all times have the products you require at the best price, with full traceability and immediate delivery.

We can guarantee the existence and availability in our warehouse of all products that have been previously requested by our customers and thus we can ensure a permanent stock of them without any obligation to purchase.

This makes us a great partner with a great service.

We are a partner for our customers.

We are: MUCH MORE THAN A WAREHOUSE.

Electromechanical Maintenance and Automation

We are a company dedicated to engineering, repair and industrial electromechanical maintenance. With personnel extensively trained in the area of engineering as well as electronic maintenance in industrial equipment and machinery.

This has made us diversify and grow in areas such as industrial electromechanical repair and maintenance, automation, renewable energies and IT services, among others.

We have duly trained and qualified technical staff, which allows us to provide quick and reliable solutions to our customers, either at our facilities at the customer’s own facilities or in the field.

Process Improvement

Process improvement is a business procedure by which inefficiencies in an organisation’s processes are searched for in order to correct them or improve their performance. It aims to review them and make the necessary adjustments to minimise or eliminate errors on an ongoing basis.

It is, of course, unrealistic to think that it is possible to optimise all processes in a company. They involve a wide variety of factors that are not always interrelated, so companies should look for those that are generating the most inefficiencies and focus on optimising them to the best of their ability.

In recent years, process improvement has become one of the top priorities for companies. The consolidation of new technologies, the need to reduce costs and new ways of working have been the main catalysts driving the need to improve the efficiency of business processes.

Process Improvement

Process improvement is a business procedure by which inefficiencies in an organisation’s processes are searched for in order to correct them or improve their performance. It aims to review them and make the necessary adjustments to minimise or eliminate errors on an ongoing basis.

It is, of course, unrealistic to think that it is possible to optimise all processes in a company. They involve a wide variety of factors that are not always interrelated, so companies should look for those that are generating the most inefficiencies and focus on optimising them to the best of their ability.

In recent years, process improvement has become one of the top priorities for companies. The consolidation of new technologies, the need to reduce costs and

new ways of working have been the main catalysts driving the need to improve the efficiency of business processes.

Engineering and Product Development

From the design and conception to the industrialisation of any product.

We manufacture and industrialise products or machines for all sectors.

Engineering adapted to the type of product to achieve investment efficiency (from the smallest to the most complex).

Always with ideas that seek from the simplest to achieve the requested challenge.